3D printing holds a lot of potential but it is limited by the number of printable materials out there. Researchers have added heat-resistant ceramic to the list, however, opening up more possibilities for additive manufacturing.

In a study published in the journal Science, researchers from HRL Laboratories showed that it is now possible to not just build but customize ceramic parts intricately while incorporating properties like strength and resistance to friction, chemical degradation and heat.

Ceramics are not known for their durability, particularly those in complex shapes, and they are compatible with traditional manufacturing methods like casting and machining. And while heat is needed to combine powders and create solid forms, it is also responsible for introducing flaws, like fractures and cracks, into the finished product.

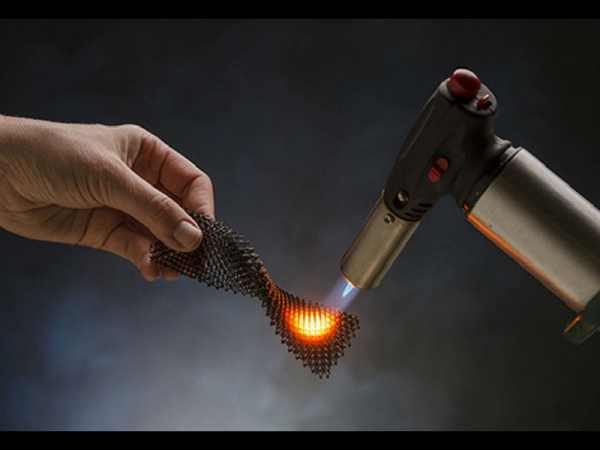

To get around this problem, HRL Labs researchers turned to printable resin made from preceramic polymers, which turn into ceramic when high heat is applied. Specifically, they showed that the resin is compatible with stereolithography, a popular 3D printing technique that utilizes a laser to create structures from liquid polymers layer by layer, as well as a specialized method 100 to 1,000 times faster than stereolithography in building lattices with patterned masks and ultraviolet light.

After printing, the resin was subjected to heat to turn it ceramic to demonstrate the material's impressive mechanical properties.

According to Tobias Schaedler, senior HRL Labs scientist, the study made it possible to print two classes of useful ceramic parts: one, small and intricate components for rockets, jet engines and electromechanical systems, and the other, large but lightweight lattice structures for air and spacecraft exteriors.

"With our new 3D printing process we can take full advantage of the many desirable properties of this silicon oxycarbide ceramic, including high hardness, strength and temperature capability as well as resistance to abrasion and corrosion," he said.

HRL Labs has also received funding from the Defense Advanced Research Projects Agency (DARPA), a supporter of the study, to utilize the new 3D printing technique to come up with a ceramic aeroshell that can be used as a shield against debris, pressure and heat for hypersonic aircraft or spacecraft.

According to DARPA's Defense Sciences Office director Stefanie Tompkins, ceramic foam is great for aeroshells but the material's poor mechanical properties make them incompatible with load-bearing structures. HRL Lab's ceramic lattice structures, however, boast of 10 times more strength than foams available commercially.

Schaedler was joined by Zak Eckel, William Carter, Chaoyin Zhou, Alan Jacobsen and John Martin in the study.

3D printing holds a lot of potential but it is limited by the number of printable materials out there. Researchers have added heat-resistant ceramic to the list, however, opening up more possibilities for additive manufacturing.

In a study published in the journal Science, researchers from HRL Laboratories showed that it is now possible to not just build but customize ceramic parts intricately while incorporating properties like strength and resistance to friction, chemical degradation and heat.

Ceramics are not known for their durability, particularly those in complex shapes, and they are compatible with traditional manufacturing methods like casting and machining. And while heat is needed to combine powders and create solid forms, it is also responsible for introducing flaws, like fractures and cracks, into the finished product.

To get around this problem, HRL Labs researchers turned to printable resin made from preceramic polymers, which turn into ceramic when high heat is applied. Specifically, they showed that the resin is compatible with stereolithography, a popular 3D printing technique that utilizes a laser to create structures from liquid polymers layer by layer, as well as a specialized method 100 to 1,000 times faster than stereolithography in building lattices with patterned masks and ultraviolet light.

After printing, the resin was subjected to heat to turn it ceramic to demonstrate the material's impressive mechanical properties.

According to Tobias Schaedler, senior HRL Labs scientist, the study made it possible to print two classes of useful ceramic parts: one, small and intricate components for rockets, jet engines and electromechanical systems, and the other, large but lightweight lattice structures for air and spacecraft exteriors.

"With our new 3D printing process we can take full advantage of the many desirable properties of this silicon oxycarbide ceramic, including high hardness, strength and temperature capability as well as resistance to abrasion and corrosion," he said.

HRL Labs has also received funding from the Defense Advanced Research Projects Agency (DARPA), a supporter of the study, to utilize the new 3D printing technique to come up with a ceramic aeroshell that can be used as a shield against debris, pressure and heat for hypersonic aircraft or spacecraft.

According to DARPA's Defense Sciences Office director Stefanie Tompkins, ceramic foam is great for aeroshells but the material's poor mechanical properties make them incompatible with load-bearing structures. HRL Lab's ceramic lattice structures, however, boast of 10 times more strength than foams available commercially.

Schaedler was joined by Zak Eckel, William Carter, Chaoyin Zhou, Alan Jacobsen and John Martin in the study.

Tel:86-21-55155796;86-21-63563197

Fax:86-21-63561543

Address:No. 3978, Baoan Highway, Anting Town, Jiading District, Shanghai

Email:wf@wfbearings.com

Website:www.hxstgy.com www.wfbearings.com

Mobile Site

Mobile Site